YLM Heavy Industry Ciencia y Tecnología duranteel proceso de desarrollo de los últimos 30 años, se fuerma una cultura empresarial y rica en contenido único.

La construcción de la cultura de la empresa YLM Heavy Industry Ciencia y Tecnología ser la cohesión y la solidaridad del punto de agregación y la fuente de energía para el desarrollo sostenible de las empresas.

Charlar en LíneaSe trata de una moderna empresa con la investigación, fabricación y ventas juntos. La matriz se encuentra enla zona HI-TECH Industry Development de Zhengzhou y cubiertas 80.000 m ².

YLM Heavy Industry

Gracias por su interés en YLM Heavy Industry. Si usted quiere saber más informaciones sobre las trituradoras y molinos de industria, contáctenos ahora para saber qué podemos hacer para su próximo proyecto.

Gracias por su interés en YLM Heavy Industry. Si usted quiere saber más informaciones sobre las trituradoras y molinos de industria, contáctenos ahora para saber qué podemos hacer para su próximo proyecto.

Address:No.169, Science (Kexue) Avenue, National HI-TECH Industry Development Zone, Zhengzhou, China

Send E-mail:[email protected]

Crushers and grinders showcase their adaptability by processing a wide range of materials used in cement production. From limestone and shale to silica and clay, these machines effortlessly...

Bavarder sur Internet

The secondary crusher (SC) is started together with C2. Conveyor C3

Bavarder sur Internet

Hammer crushers can be divided into several types: 1) Based on rotor amount: single

Bavarder sur Internet

Crushers and grinders showcase their adaptability by processing a wide range of materials used in cement production. From limestone and shale to silica and clay, these machines effortlessly...

Bavarder sur Internet

The crusher uses a single hammer rotor with peripheral speed of about 40 meters per second. No inlet grating is necessary as the crusher is fitted with rollers to absorb the shock of the large rocks in the feed. The crusher is suited to handle materials containing a certain proportion of the sticky material.

Bavarder sur Internet

The secondary crusher (SC) is started together with C2. Conveyor C3 will start after a . ... (tpd) dry process cement plant situated at Jayanthipuram, Andhra Pradesh, India ...

Bavarder sur Internet

Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

Bavarder sur Internet

The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them. Raw material preparation: use cement mill to process materials into required sizes for cement clinker production.

Bavarder sur Internet

In short, the cement plant should blend beautifully with its surroundings. 1.11. Scope for making and designing green cement plants. The cement industry is consciously making efforts in various areas (listed in section 1.8) and is very much interested in making existing plants green and in designing new plants as green plants. 1.11.1. Blended ...

Bavarder sur Internet

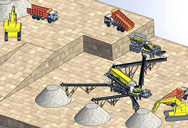

A stone crushing plant is primarily involved in the manufacture of aggregates of various sizes (coarse aggregates, crusher run, rock sand and other fine aggregates) from basalt boulders. Coarse aggregates are usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for road making.

Bavarder sur Internet

The manufacture of cement is a very carefully regulated process comprising the following stages: 1. Quarrying - a mixture of limestone and clay. 2. Grinding - the limestone and clay with water to

Bavarder sur Internet

The cement roller press, also known as roller press in cement plant, high pressure grinding roll (HPGR), is a kind of cement equipment for brittle materials, apply for grinding cement clinker, cement raw material, gypsum, coal, quartz sand, iron ore, blast furnace slag, and other materials.

Bavarder sur Internet

In the production process, large stones are evenly sent to the jaw crusher by a vibrating feeder for coarse crushing (primary crushing), then sent to the impact crusher by the belt conveyor for secondary crushing. After

Bavarder sur Internet

Here are the basic steps involved in setting up a cement plant: Conduct a feasibility study: This will involve analyzing the market demand for cement, the availability of raw materials and other ...

Bavarder sur Internet

Stage 2: Grinding, Proportioning, and Blending The crushed raw ingredients are made ready for the cement-making process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture. The composition of cement is proportioned here depending on the desired properties of the cement. Generally, limestone is 80%, and the

Bavarder sur Internet

Make Better Decisions with the Connected Cement Plant. Global cement demand is set to grow by up to 23% in the next 30 years. ... application can be applied to any process area in cement production. Lean More About Process Optimization and MPC ... application provides control and optimization of the crushing or grinding cement finish mill ...

Bavarder sur Internet

Hot-sale Cement Equipment. AGICO is a leading cement equipment manufacturer in China, supporting high-quality cement kilns, cement mills, cement crushers, industrial dust collectors, conveying equipment, and other machines that are needed in the cement plant. We offer customization, installation, commissioning, and operation training services.

Bavarder sur Internet

Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

Bavarder sur Internet

The secondary crusher (SC) is started together with C2. Conveyor C3 will start after a . ... (tpd) dry process cement plant situated at Jayanthipuram, Andhra Pradesh, India ...

Bavarder sur Internet

The cement plants working with wet process achieve a heat consumption of approximately 5030 kJ/kg-clinker. This is possible by reducing the water content from 48% to about 30% by employing slurry thinners.

Bavarder sur Internet

Stage 2: Grinding, Proportioning, and Blending The crushed raw ingredients are made ready for the cement-making process in the kiln by combining them with additives and grinding them to ensure a fine homogenous mixture. The composition of cement is proportioned here depending on the desired properties of the cement. Generally, limestone is 80%, and the

Bavarder sur Internet

A stone crushing plant is primarily involved in the manufacture of aggregates of various sizes (coarse aggregates, crusher run, rock sand and other fine aggregates) from basalt boulders. Coarse aggregates are usually used in ready mix concrete and asphaltic concrete. Crusher run is used for the bases and sub-bases for road making.

Bavarder sur Internet

Our Model Predictive Control (MPC) application provides control and optimization of the crushing or grinding cement finish mill processes through patented, industry-leading technology. Download Now Technical

Bavarder sur Internet

Further, the raw material with granulation of up to 800 mm has to be transported via dump trucks to the hammer crusher, where it is crushed to the granulation of 0–80 mm for marl and 0–50 mm for

Bavarder sur Internet

Here are the basic steps involved in setting up a cement plant: Conduct a feasibility study: This will involve analyzing the market demand for cement, the availability of raw materials and...

Bavarder sur Internet

The cyclone preheater uses the high-temperature airflow accumulated in the kiln and adopts a multi-stage circulating suspension preheating method to make the raw material powder and the hot air flow fully exchange, complete the suspension preheating and partial raw material decomposition, and prepare for the clinker production.

Bavarder sur Internet

In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by

Bavarder sur Internet

The cement manufacturing process in the plant can be divided into seven steps: Step 1 – Raw Material Crushing Pre Homogenization: In the Portland cement manufacturing process, most raw materials need to be crushed first,

Bavarder sur Internet

Crushing to the proper size usually occurs in stages because rapid size reduction, accomplished by applying large forces, commonly results in the production of excessive fines (Rollings and Rollings 1996). After primary crushing, the material is run through one or more secondary crushers.

Bavarder sur Internet

2.1 Cement Manufacturing Process The flow chart below shows the process of cement manufacturing Figure 1: Process Flow Chart It involves the following steps: ♦ Pre-blending of crushed limestone. ♦ Drying – cum-grinding of raw materials. ♦ Homogenization of raw meal in a blending silo.

Bavarder sur Internet

Some tips to keep a safe crusher: Operate at the appropriate capacity. Keep platforms and areas around the machine clean. Ensure lubrication, flow, temperature, wear and pressure are monitored. Another crushing plant with clear walkways that are free from debris and proper guards on moving parts.

Bavarder sur Internet