YLM Heavy Industry Ciencia y Tecnología duranteel proceso de desarrollo de los últimos 30 años, se fuerma una cultura empresarial y rica en contenido único.

La construcción de la cultura de la empresa YLM Heavy Industry Ciencia y Tecnología ser la cohesión y la solidaridad del punto de agregación y la fuente de energía para el desarrollo sostenible de las empresas.

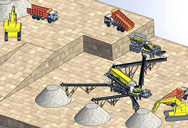

Charlar en LíneaSe trata de una moderna empresa con la investigación, fabricación y ventas juntos. La matriz se encuentra enla zona HI-TECH Industry Development de Zhengzhou y cubiertas 80.000 m ².

YLM Heavy Industry

Gracias por su interés en YLM Heavy Industry. Si usted quiere saber más informaciones sobre las trituradoras y molinos de industria, contáctenos ahora para saber qué podemos hacer para su próximo proyecto.

Gracias por su interés en YLM Heavy Industry. Si usted quiere saber más informaciones sobre las trituradoras y molinos de industria, contáctenos ahora para saber qué podemos hacer para su próximo proyecto.

Address:No.169, Science (Kexue) Avenue, National HI-TECH Industry Development Zone, Zhengzhou, China

Send E-mail:[email protected]

The researchers find out availability of quality fluorite concentrate in processing of low-grade ore with carbonate index less than 1 at CaF2 recovery up to

Bavarder sur Internet

In this work, we attempted to study the heterocoagulation in the fluorite ore slurry from the Minera de los Cuervas fluorite concentration plant, located in the state of

Bavarder sur Internet

The authors describe studies into dressability of mill tailings from tailings pond of processing plant of Yaroslavsky Mining Company. It is found that the Prospects

Bavarder sur Internet

solutions intended to improve efficient fluorite recovery from rebellious ores including mill wastes. Outbalance ore dump reserves of less than 23% СаF2 grade and carbonate

Bavarder sur Internet

Fluorite ore processing plant. 1. Africa 100TPD fluorite ore processing plant. In a fluorite beneficiation plant in Africa, fluorite and quartz are the main

Bavarder sur Internet

A fluorite dressing plant in Hebei, the fluorite with low ore grade, high oxidation, fine granularity distribution and small hardness, the original production process was

Bavarder sur Internet

In this article, we're going to talk about the processing of fluorite ore, we're going to explain it in 4 parts, including: Fluorite Processing Methods. Quartz-Fluorite Ore Flotation Flowsheet. Carbonate-Fluorite

Bavarder sur Internet

The ore has the following content of the main components: 41,3% of fluorite; 40,5% of quartz; 10,5% of calcite. Nowadays, the concentrating mill of ldquo;Bor Undurrdquo;

Bavarder sur Internet

The core equipment of fluorite gravity separation is a mineral jig machine. It can process fluorite ore with a particle size of 0-50mm. Related auxiliary equipments are crushers, vibrating screens, etc.

Bavarder sur Internet

3D modeling was undertaken to establish the morphology, volume, and spatial distribution of the fluorite orebody, and ore grade of Jbel Tirremi located in northeastern Morocco. The ore is hosted in the intensely fractured Jurassic carbonates. The mineralization is structurally controlled because it is primarily hosted in N–S- and

Bavarder sur Internet

Some fluorite processing plants are located in northern China, which is characterised by long cold winters, necessitating thermal heating of the ore slurry translating to high energy costs. Apart from the proper selection of depressants, high-temperature pulp treatment has also been shown to improve the selectivity in fluorite flotation [ 2 , 3 , 4 ].

Bavarder sur Internet

The ore sample used in this work was collected from the feed ore of the fluorite flotation circuit in the Minera de los Cuervas (MLC) concentration plant. The sample contained 85.86% CaF 2, 6.41% CaCO 3 and 4.29% SiO 2. The particle size distribution was shown in Fig. 1. The d60 (diameter at the cumulative undersize of 60%) of the

Bavarder sur Internet

The full-scale implementation of the selective carbonate-fluorite ore flotation to recover fluorite without high-temperature pulp treatment at the ore-preparation plant of the Yaroslavl Mining Company made it possible to cut down the thermal energy costs and to work profitably in the times of the economic crisis (Fig. 2). Fig. 2.

Bavarder sur Internet

Flowsheet of an operating acid-grade fluorspar plant treating 300 tons of ore per day. Rougher flotation concentrates are ground to —200 mesh prior to cleaning. Acid-grade fluorspar is 98 per cent

Bavarder sur Internet

1. Introduction. The main challenge for rare earth element (REE) extraction from primary deposits is the low concentration of REE-bearing minerals present in a variety of gangue minerals, including silicates, carbonates, fluorites, and/or phosphates (Vijayan et al., 1989).Among the residues generated during the pre-concentration of rare earth

Bavarder sur Internet

Some fluorite processing plants are located in northern China, which is characterised by long cold winters, necessitating thermal heating of the ore slurry translating to high energy costs.

Bavarder sur Internet

REEs are product of diverse and intricate genesis, and are found in a variety of host minerals, including phosphates, silicates, carbonates, halides, and oxides (Rim et al. 2013; Suli et al. 2017 ...

Bavarder sur Internet

Nowadays, the concentrating mill of “Bor Undur” ore-dressing and processing plant, processes the high-carbonate ore of Urgen deposit only in the mixture (to 16%) by the currently extracted ores. As a result of the laboratory researches, there was obtained the fluorite concentrate, which contains 97,5% of fluorite, 0,94% of quartz, 0,01% of sulfur

Bavarder sur Internet

The researchers find out availability of quality fluorite concentrate in processing of low-grade ore with carbonate index less than 1 at CaF2 recovery up to 70%. Discover the world's research 20 ...

Bavarder sur Internet

Some fluorite processing plants are located in northern China, which is characterised by long cold winters, necessitating thermal heating of the ore slurry translating to high energy costs. Apart from the proper selection of depressants, high-temperature pulp treatment has also been shown to improve the selectivity in fluorite flotation [ 2 , 3 , 4 ].

Bavarder sur Internet

REEs are product of diverse and intricate genesis, and are found in a variety of host minerals, including phosphates, silicates, carbonates, halides, and oxides (Rim et al. 2013; Suli et al. 2017 ...

Bavarder sur Internet

1. Introduction. The main challenge for rare earth element (REE) extraction from primary deposits is the low concentration of REE-bearing minerals present in a variety of gangue minerals, including silicates, carbonates, fluorites, and/or phosphates (Vijayan et al., 1989).Among the residues generated during the pre-concentration of rare earth

Bavarder sur Internet

Flowsheet of an operating acid-grade fluorspar plant treating 300 tons of ore per day. Rougher flotation concentrates are ground to —200 mesh prior to cleaning. Acid-grade fluorspar is 98 per cent —325 mesh. No pumps are used for handling froth in flotation cleaner circuits. Fluorite Reagent Combinations

Bavarder sur Internet

Nowadays, the concentrating mill of “Bor Undur” ore-dressing and processing plant, processes the high-carbonate ore of Urgen deposit only in the mixture (to 16%) by the currently extracted ores. As a result of the laboratory researches, there was obtained the fluorite concentrate, which contains 97,5% of fluorite, 0,94% of quartz, 0,01% of sulfur

Bavarder sur Internet

2 Flotation Processes of 4 types of associated fluorite. Just as is the case with almost ore processing and non-metal beneficiation, the concentrate fluorite is extracted by crushing, sieving, grinding, grading, flotation, filtration, drying, etc. How to realize the high-efficiency sorting of associated fluorite ore is a real problem in the ...

Bavarder sur Internet

According to the different gangue minerals, fluorite ore can be divided into four types, namely quartz fluorite ore, carbonate fluorite ore, barite fluorite ore and ... 7 Tips for Energy Saving and Consumption Reduction in Mineral Processing Plant. 2022-02-24(02:02:02) Tag. Flotation Thickener Ball Mill Screening Equipment Classifier ...

Bavarder sur Internet

The researchers find out availability of quality fluorite concentrate in processing of low-grade ore with carbonate index less than 1 at CaF2 recovery up to 70%. Discover the world's research 20 ...

Bavarder sur Internet

Some fluorite processing plants are located in northern China, which is characterised by long cold winters, necessitating thermal heating of the ore slurry translating to high energy costs.

Bavarder sur Internet

The core equipment of fluorite gravity separation is a mineral jig machine. It can process fluorite ore with a particle size of 0-50mm. Related auxiliary equipments are crushers, vibrating screens, etc. If you are interested in a fluorite ore gravity separation plant, please contact us. phone/whatsApp: +8613592513050.

Bavarder sur Internet